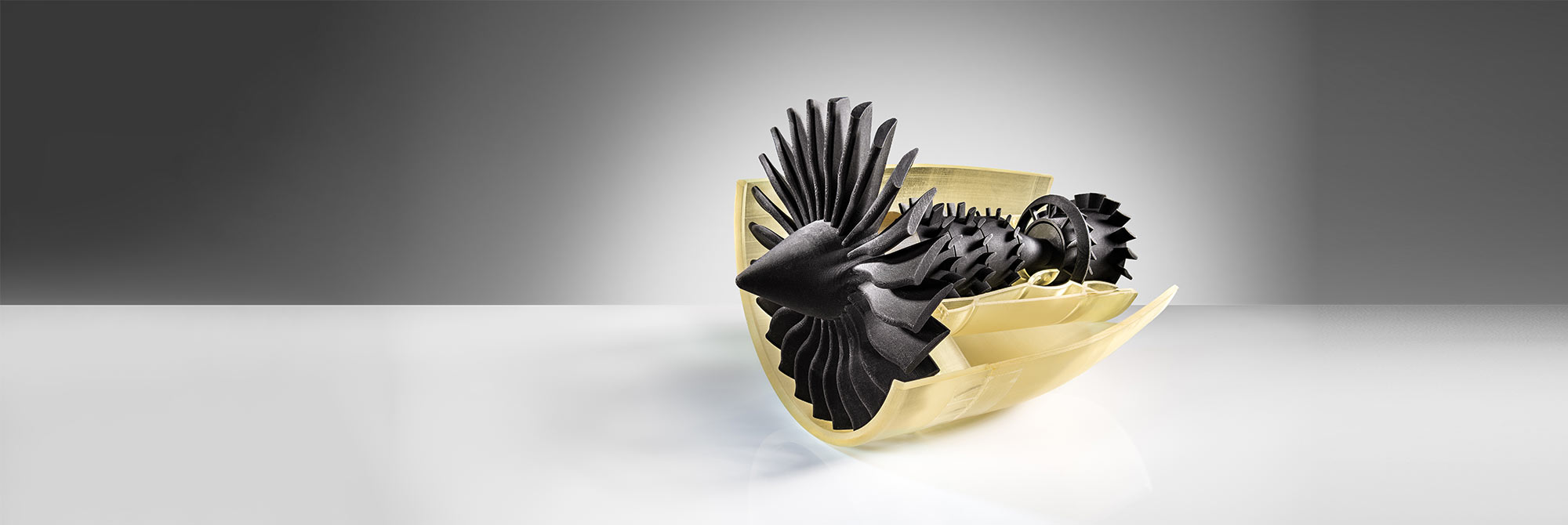

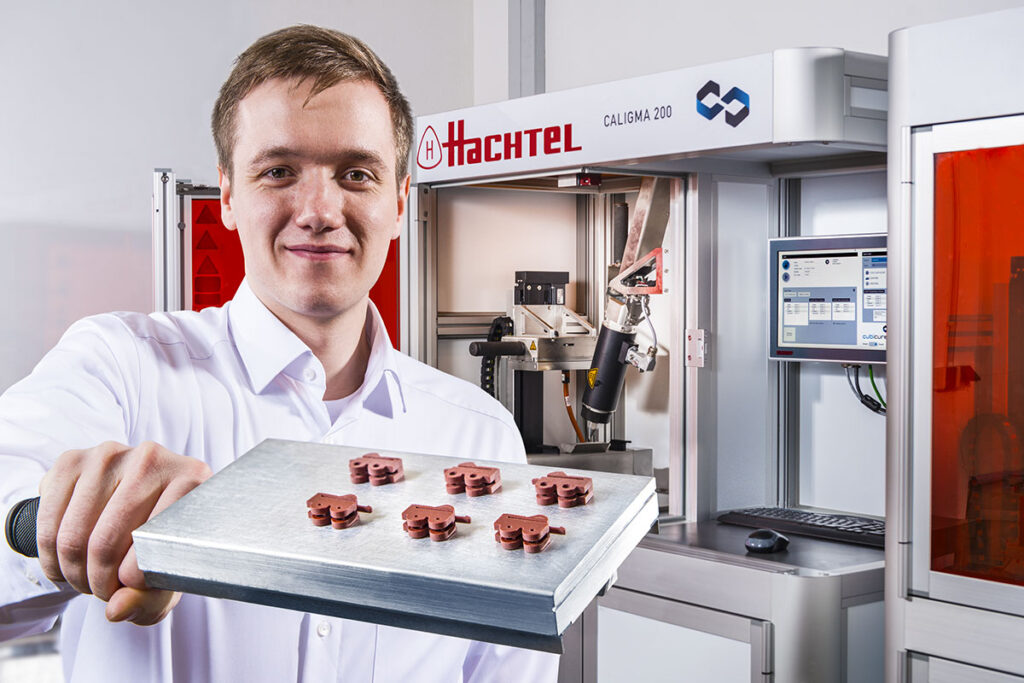

Hot lithography is a laser-based 3D printing process that uses a special heating and coating mechanism to additively manufacture precise plastic parts with good mechanical properties. The hot lithography technology allows highly viscous and highly molecular starting materials to be processed.

Patented hot coating technology

The resins are heated to 120° C to bring them to a workable state. A special hot layer technology allows the temperature to be regulated precisely and individually during the various process steps. This prevents overheating and thus uncontrolled polymerization of the material.

The 3D object is built up in layers 50-100 µm thick. A new layer is created by immersing the partially manufactured component in the liquid resin layer and a laser exposes and thus polymerizes the areas that are materialized. The combination of liquid raw material and high-precision laser polymerization enables unbeatable precision, resulting in uniquely smooth surfaces.

Facts and features of Hot Lithography

Technical information

- Wall thicknesses from 0.1 mm

- Layer thickness between 50 µm and 100 µm

- Components up to 100 mm x 200 mm x 300 mm

- Beam diameter in the laser focus of up to 10 µm for high structuring accuracy

Advantages at a glance

- Production of high-precision plastic parts that are ideally suited for industrial applications

- Temperature resistance of printed components up to 300° C

- First-class surface quality

You can find out more about the process and materials at Cubicure.