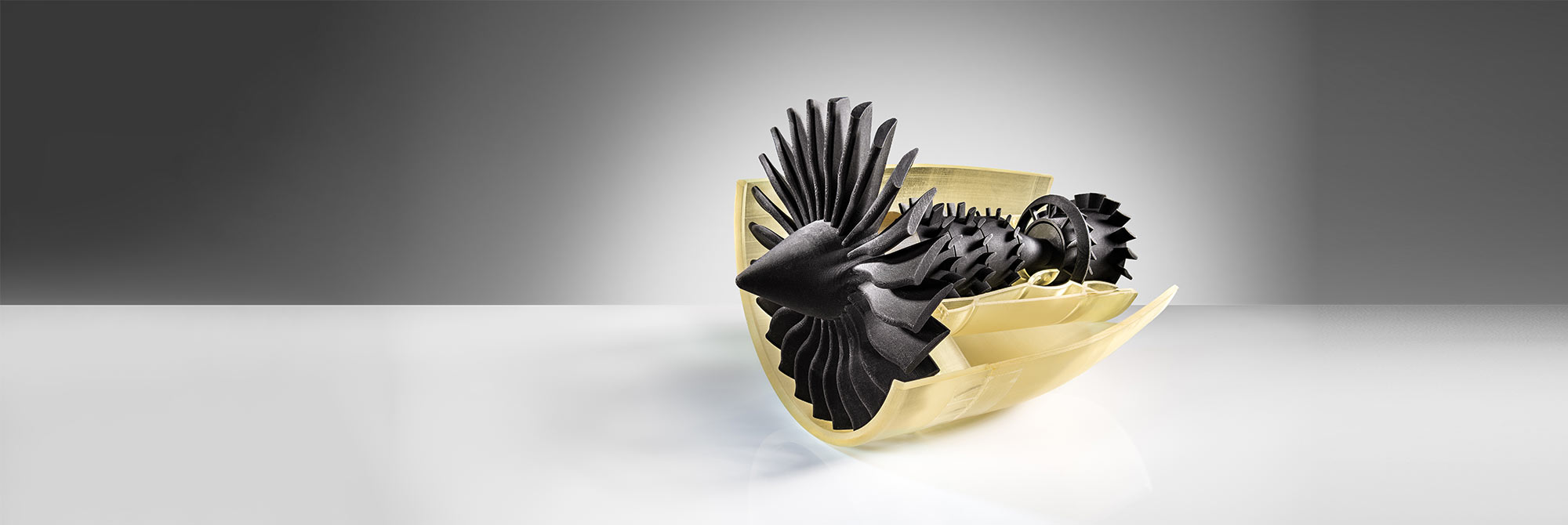

Highest precision, smooth surfaces, and excellent thermal and mechanical properties characterize the 3D-printed components from Hachtel. The processing of high-performance photopolymers using the “Hot Lithography” process makes it possible.

Since we manufacture plastic injection-molded parts in-house, we have high demands on 3D-printed components and know exactly about the practical requirements in the industry.

Surfaces like injection-molded parts

We obtain very good surfaces of the 3D printed components without intense post-processing, comparable to injection molding.

3D-Prints with highest precision

We produce very precise components using additive manufacturing. This is due to the structuring accuracy, which is achieved using a very fine laser diameter of 10 µm.

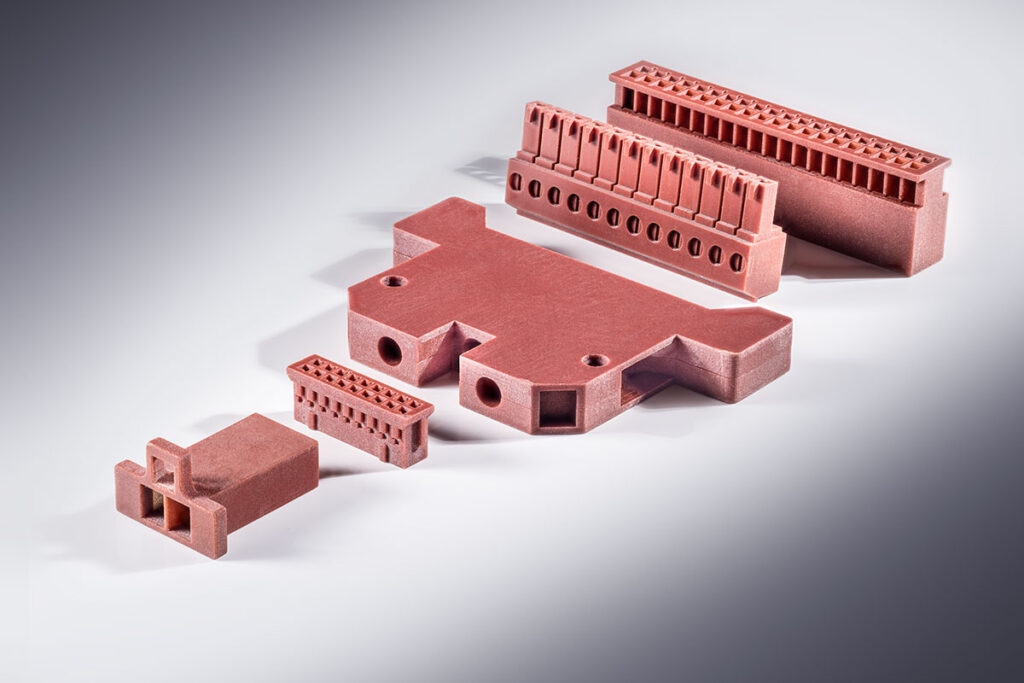

Heat-resistant components up to 300 °C

In the hot lithography process, we can use a highly heat-resistant material. It can withstand ambient temperatures of up to 300 °C and is also resistant to chemicals. This makes it particularly suitable for applications in the electronics and aerospace industries.

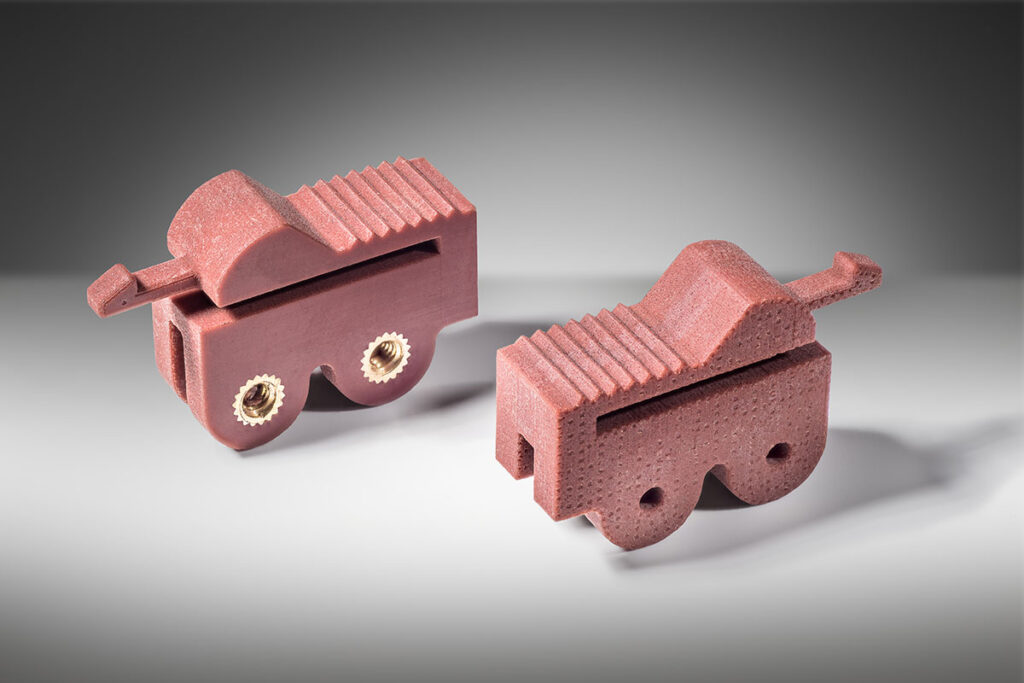

Flame-retardant materials

In the event of a component fire, the components in many applications must have self-extinguishing properties. We achieve this with a material that has UL94 V0 classification. This enables use in rail vehicles as well as in the automotive and energy sectors.

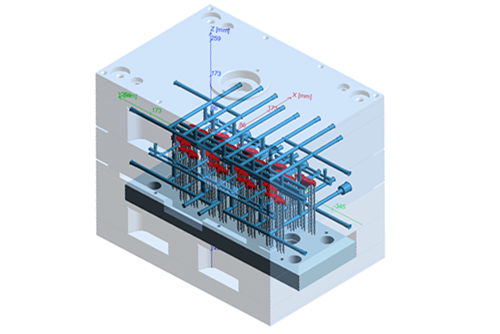

No 3D data set available?

We help you to create a print template. To do this, we use our talented design team to construct a CAD model according to your specifications. Alternatively, we can digitize your existing component using CT and prepare it as a print template.

Large quantities?

We can advise you on the quantities from which plastic injection molding is the optimum solution for your project.