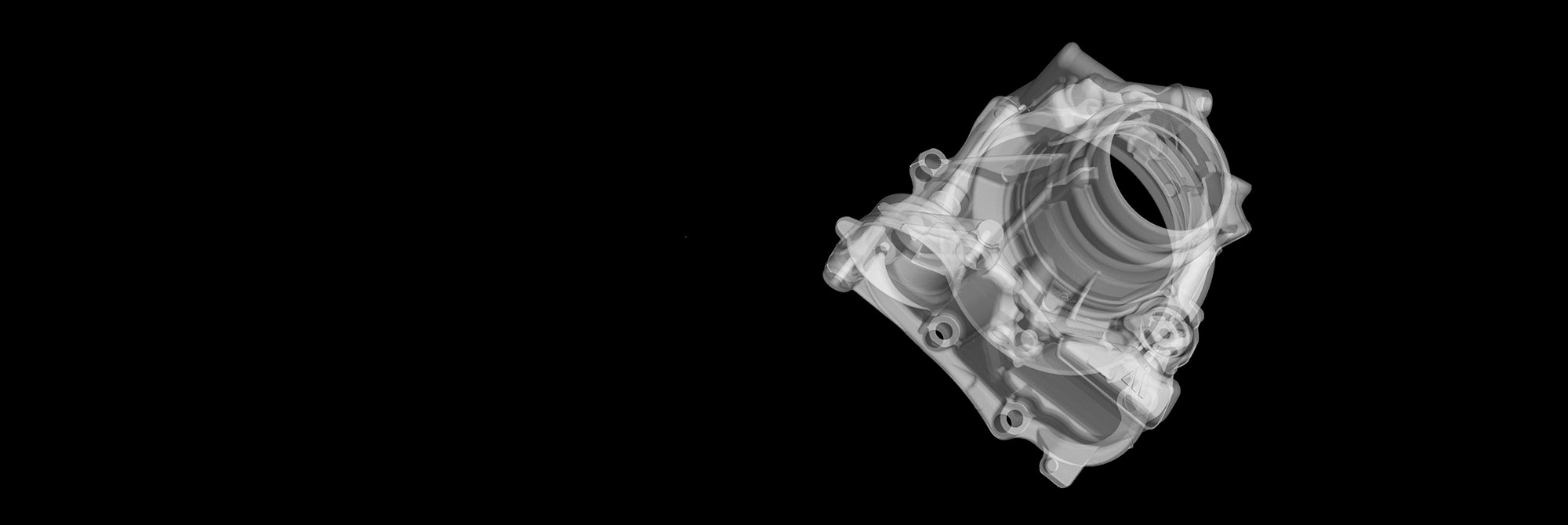

Industrial computed tomography enables you to perform various evaluations based on the 3D data set (digital twin), for example in metal casting, plastic injection molding or additive manufacturing.

Automated measurement sequences for series testing and various alignment options can be realized with the help of industrial computed tomography.

Metrology

Absolutely transparent measurement is possible on the digital twin of your component created using computer tomography. The measuring points are easily traceable and reliably reproducible. This simplifies documentation in the initial sample test report (FAI) and subsequent verification of the measurement results.

Dimensional accuracyFormtreue (nominal/actual, actual/actual)

The software reconstructs the surfaces of the various materials from the digital twin (surface traceability). These can be compared with the CAD model of the component (target/actual) or another digital twin (actual/actual).

Deviations can be displayed in color according to their size. This so-called false color representation enables a quick and meaningful illustration of the dimensional accuracy, i.e. deviations and distortions over the entire component. This means that external and internal contours can be easily evaluated and local deviations can be displayed using analysis markers.

Porosity analysis

Your component is fully X-rayed, which means that not only surfaces but also all internal contours are imaged and digitized. This makes it possible to examine the sample for defects and blowholes and then output quantitative information and statistics.

This allows you to carry out non-destructive P201 and P202 analyses or check whether pores would be cut through before the component is machined. Defect and void analysis is a very helpful tool when optimizing plastic or metal casting processes.

Assembly analysis

We analyze your assemblies using an X-ray image, 2D live view or a 3D computed tomography scan. For example, you can check the location and position of visible and concealed components in the assembly, as well as internal components for faults. Everything is possible, from inspecting solder joints in memory chips to checking the positioning of catalytic converters and exhaust systems during assembly.

The example image shows a 2D sectional plane of a coil; question: How are the wires positioned?

Flexible materials like silicones or elastomeres can be perfectly scanned like rigid bodies with x-rays and the be measured.

Using specialized fixtures we can test assemblies in their function, just like the deformation of this silicone-membrane under different pressures.

Reseller for Volume Graphics software

If you would like to carry out your analyses yourself, we can support you in selecting and purchasing Volume Graphics software. We are an official reseller and can offer you the entire portfolio. We bring our many years of expertise to bear for you and configure your VGSTUDIO MAX with you, develop test plans for VGinLINE or create your first EMPB with VGMETROLOGY together with you.

After purchasing the software, we won’t leave you on your own: we offer you all the support you need to get productive as quickly as possible. We invite you to our premises to carry out scans with you and then process them. We come to you on site to integrate your process optimally. We connect with you via the Internet to help you quickly and easily.